I have not the slightest idea of the condition of the engine from the donor bike.

I know it was a 350 on, or close to its largest overbore.

I know it hasn’t been run or turned over for over a decade.

So I think it’s time to have a look at it.

When I embarked on this project, I knew that it was unlikely that I’d find anything usable from the engine, but I had an ace up my sleeve.

As a long time LC owner, I had developed the habit of keeping a known good engine in the garage to quickly swap out when the inevitable seizure happened.

The spare engine gets turned over every few months in order to keep the seals moist and moving, but I have not needed it for over 10 years, so it has been earmarked for this project if needed.

Here it is hidden away in the corner, under the workbench.

Rather than just stick the spare engine in the frame though, I want to have a look at what i inherited with the donor bike.

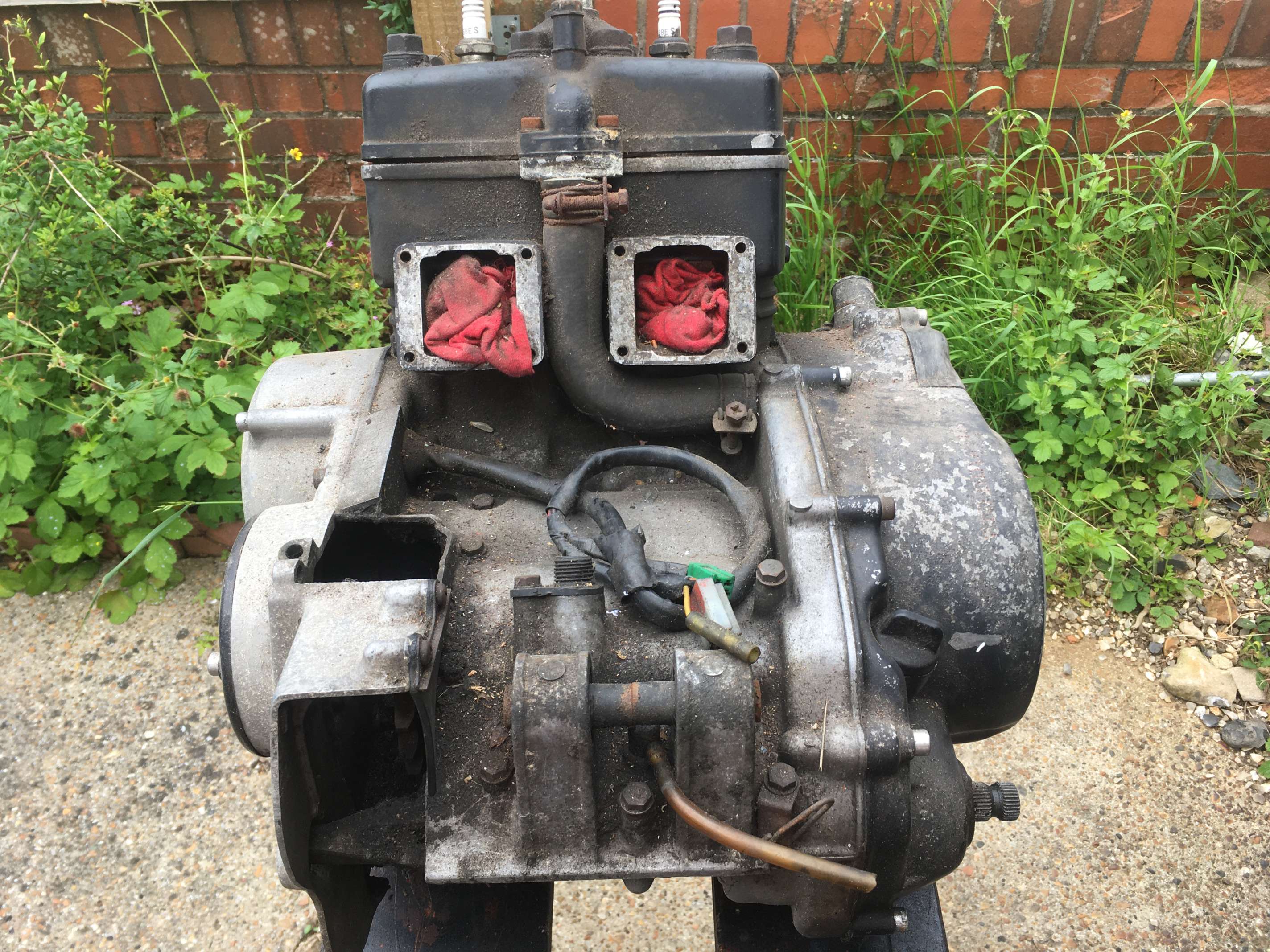

Well obviously it’s filthy. I scraped the worst of the black goo off… the rest I’ll remove in stages during the strip down.

Visually, I can see already that i need a new gear change shaft, as the splines are all but gone. I’m sure I have a new one knocking around somewhere.

On the wiring harness is the other half of the butchered alternator wiring, so I’ll be ordering the correct connector and fitting that. (I really should have thought this through before making the first order and saved myself some postage).

…but the engine turns over with no ominous scratching or clanking. The pistons go up and down as they should, aided by the oil I shoved down the plugholes when the bike first returned home.

Draining the oil showed very little of it, and what there was was quite, quite black.

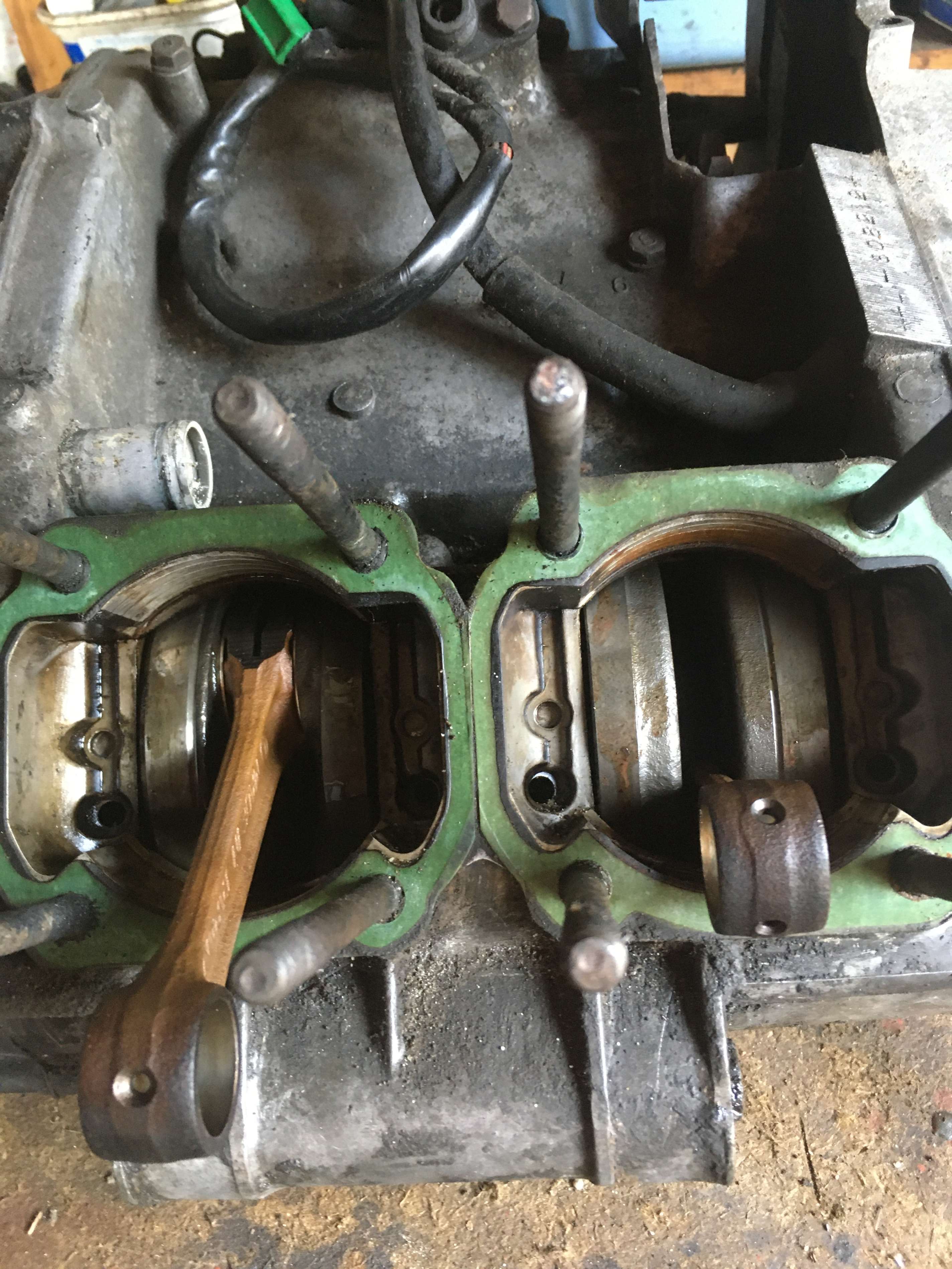

Removing the head showed no huge issues. It has been well used, and the barrels are lightly scored, but nothing terrible. After a quick clean up and running a hone down the barrels, I’d probably build it back up and use it… except for the missing ring locator pin on one piston.

The bores are at 1.50mm oversize, so there is room for one more rebore if needed.

Exhaust and inlet ports don’t appear to have been altered, but I’d need to measure to be sure. the transfer ports have been lightly knife edged though, so maybe someone has “tickled” it slightly in the past.

I wonder if I have a +1.50 piston in the parts box?

Once the top end was off I could have a preliminary look at the crankshaft.

the top of one small end is blackened a bit, as if one side had overheated at some point, but both small ends and bearings are in good condition.

There is no discernable vertical movement in the big ends, and there is evidence that some oil had made its way into the crank casings helping to preserve the bearings, which feel smooth.

I’ll be splitting the crankcase halves anyway, but with the addition of two new crankcase oil seals, I can see myself reusing the crank.

So baring discovery of disasters in the tear down, my spare engine can remain under the workbench, and I’ll refurbish and reuse this bottom end, with a decent 250 top end.

I’m sure there will be plenty of reluctant nuts and bolts to go through yet, and a great deal of filth to remove from the outside, and probably the inside, but all told, this engine is in better condition than I could have hoped.