More pottering in the garage Yesterday with only a nebulous list of things to do.

So a quick update on previous Blog Posts in picture form below.

The center stand is filthy, to be expected after living under a motorcycle all its life, then being stored in a dank shed for 15 years.

The center stand connecting pin is quite rusty, but may clean up sufficiently for reuse.

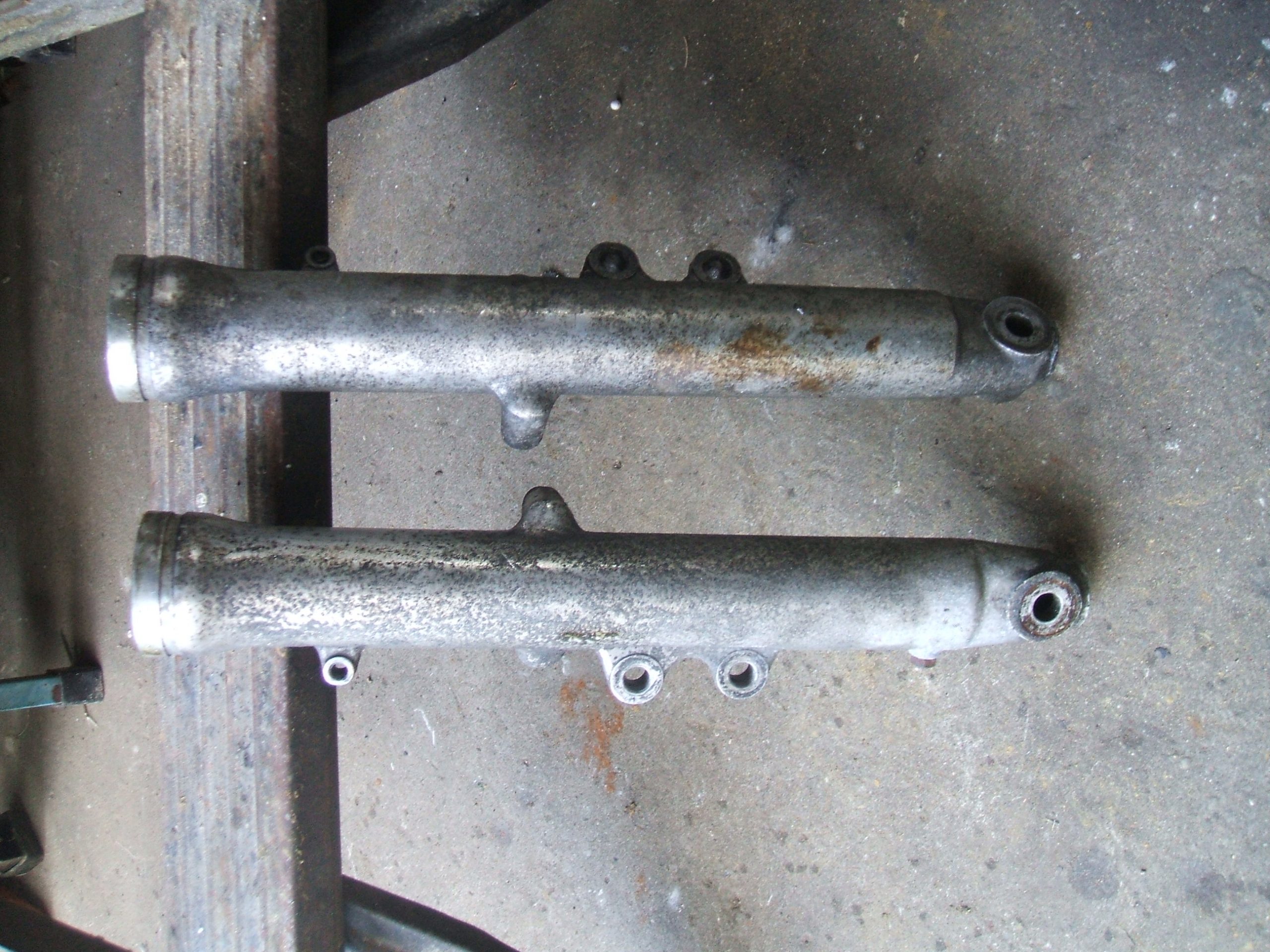

The fork legs, now mercifully released from their old stanchions, are in a poor state.

On the bright side, the swingarm has come up well, and needs just one more blow-over with the black enamel spray to be acceptable.

I set to work on the stand in the paraffin bath, but apart from some surface dirt it was having little effect. I switched to using a rotary wire brush on the drill, and immediately saw an improvement.

I finished off with a toothbrush and copious amounts of brake cleaner.

I didn’t get into all of the corners, but this is not a cosmetic build, and a blow-over with black paint is all that’s needed at this point.

I keep telling myself that if I make the cosmetics too acceptable on this build, then I’ll have no incentive to take it apart again once finished to apply all the cosmetic touches.

The pin was cleaned with a rotary wire brush.

When I cleared out under the workbench, I found the Spax shock which I bought many years ago. It had never been fitted to the bike permanently because it felt far too stiff.

Looking at it (on the right), in comparison with the Spax shock from the donor bike (on the left), it is clear that the spring on the right has many more coils than the other. It is probably for a car, although the damper mechanism underneath looks identical.

Either way, close examination shows corrosion on the shaft of BOTH shocks, so these both return to the parts bin in the shed, and I’ll go with a standard LC shock for the build.

The fork legs are pitted and corroded.

I had read somewhere that the best way to approach this kind of damage was with a nylon scouring pad, using WD40 as a lubricant.

After an hour of elbow grease, one wrecked scouring pad, and half a can of WD40, and can confidently say that I don’t believe that this is the best approach.

I managed to half clean one fork leg.

there must be a better way!

Today, I took it easy.

A light coat of black enamel on the center stand and the torque arm, and sorting out the bolts for the upper and lower yokes.

Photos to come when they are finished.