I cut the side-stand bracket off my RD350LC. It had been rewelded wrong.

I have either a new (YPVS) bracket to weld back on, or I will “remake” the one which I removed.

The key issue for me though, is to ensure that when remounted, and used with a standard LC side-stand, the bike will sit at the correct angle, and not fall over.

Fortunately, I have another LC. A 250, which has a bracket attached, and a side-stand fitted which does the job just fine.

All I need to do is replicate the mounting angles onto the 350 frame, right?

Just eyeball it into place.

No. I need some sort of jig to locate the bracket in the right place before I attach it to the frame.

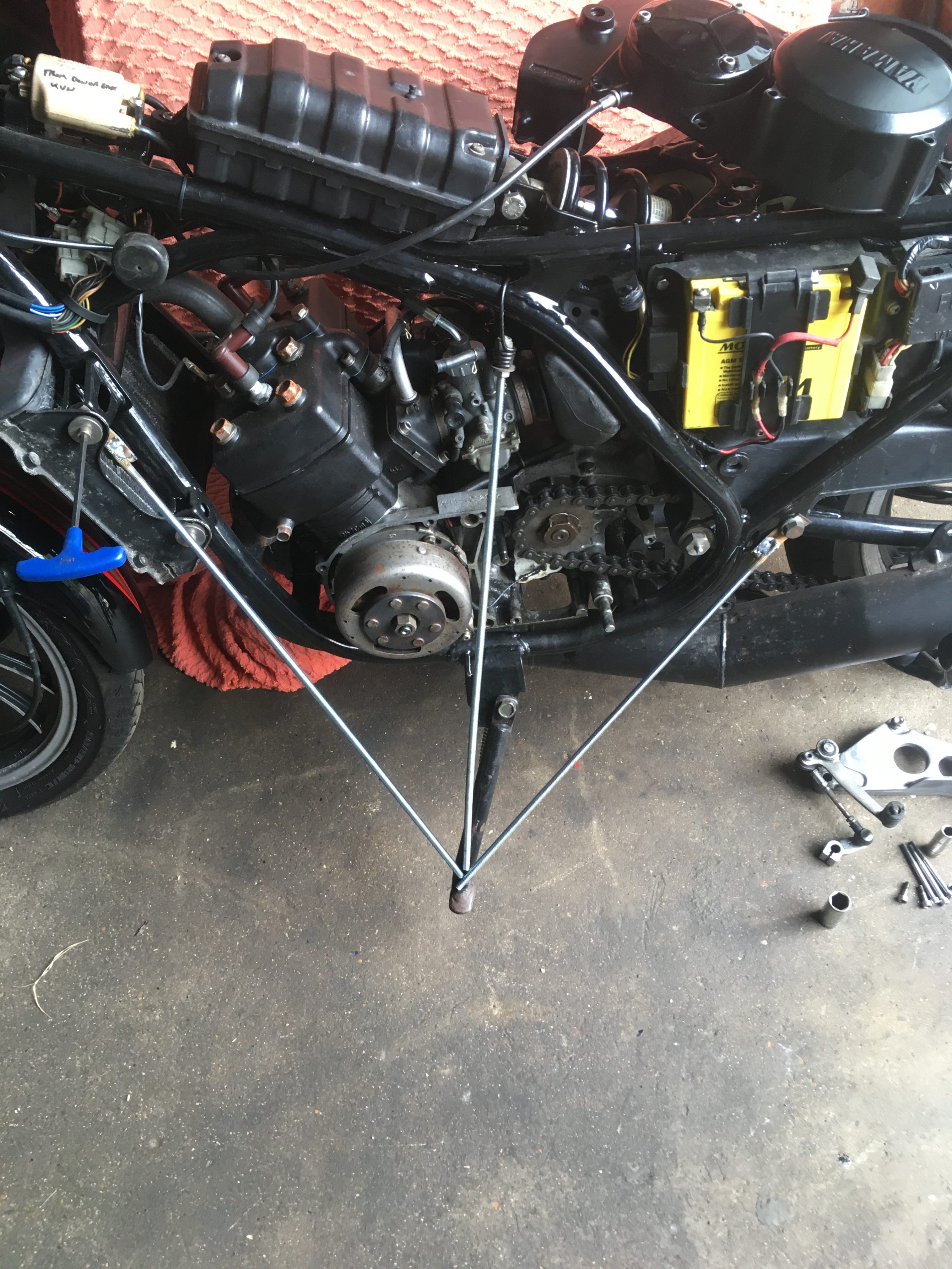

After some thought, I came up with an idea to locate the bracket in the correct 3 dimensional space with regard to 3 points on the frame.

All I need is some scraps of steel sheet, some tie rods of some description, an old side-stand, and a welder.

A bit of preparation, before I approach the 250 for fitting it all together.

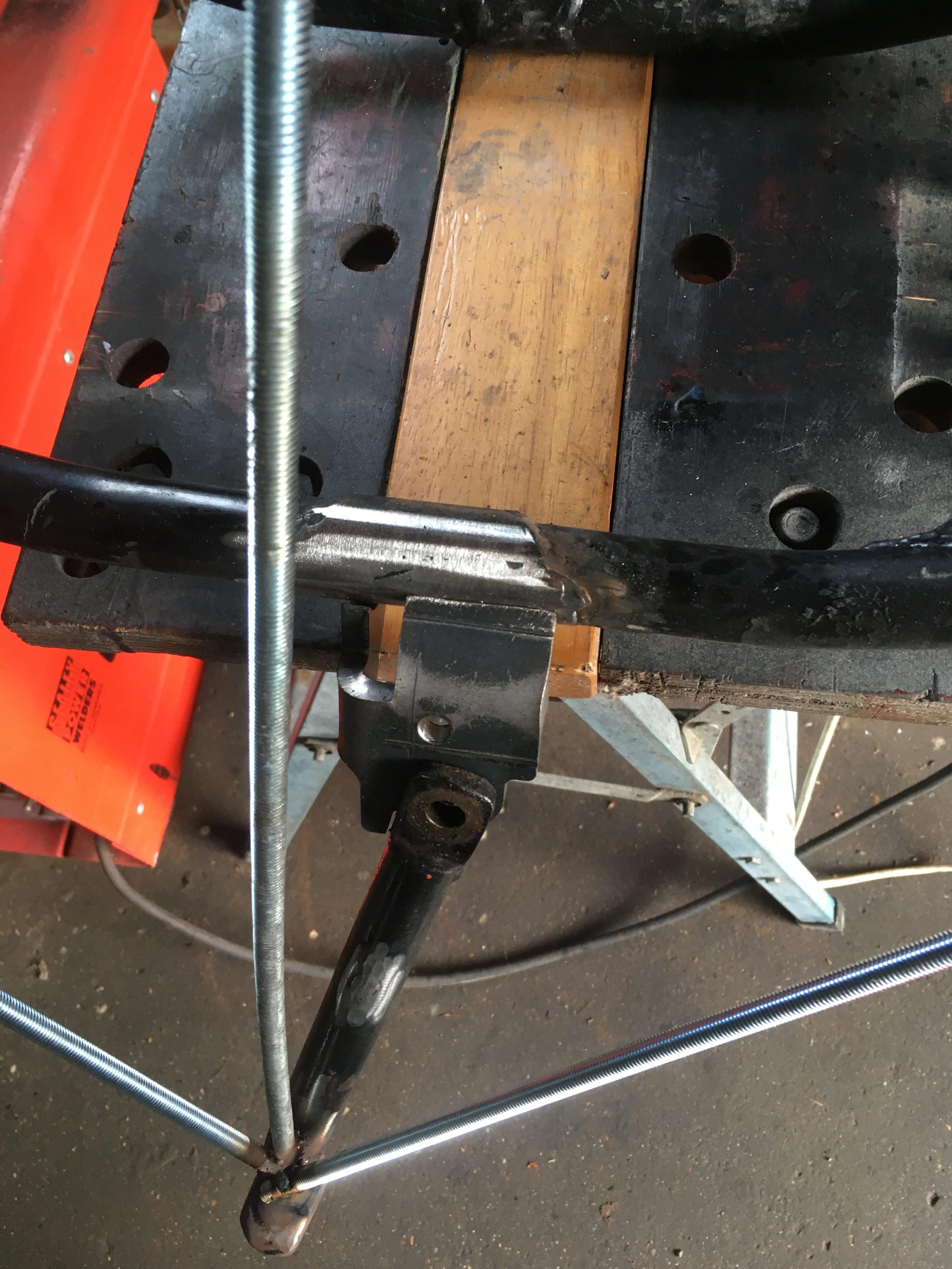

I know where 2 of the tie bars will be mounted, requiring a 6mm and a 10mm hole to be drilled, but there is no obvious third mounting point, so I decided to use a hook around the frame, repurposing an old bungee end.

For the tie rods, I ended up with some lengths of 8mm threaded rod, that being around a quarter of the price of 8mm bar, or for that matter, anything else I could source.

I now have three lengths of terminated 8mm threaded bar, and an old side-stand.

Lets offer them up to the 250 and see if the idea will work.

I need to remove the original side-stand, (because I don’t want to weld anything to that!), and it turned out, that for clearance, I needed to remove the left hand engine cover.

The welding doesn’t have to be perfect, (or even good 🙂 ), which is good, because the quality of the steel in the rods, and the coating, made the welding quite difficult.

The sacrificial side-stand needed to be bolted to the frame, with spring, such that it is held properly in place, in a repeatable way.

Once the welding was completed, I could remove the side-stand bolt, and gently tap the top of the side-stand, sideways, until it disengaged with the bracket.

The resulting assembly is sturdy enough to do this one job.

Let’s see what it looks like on the 350 frame, with the YPVS bracket offered up.

Interestingly, the bracket does not align perfectly with the sleeve on the bottom frame rail. I wonder whether these are reliably in the same place on every frame?

I didn’t think to measure when I had the tape-measure out.