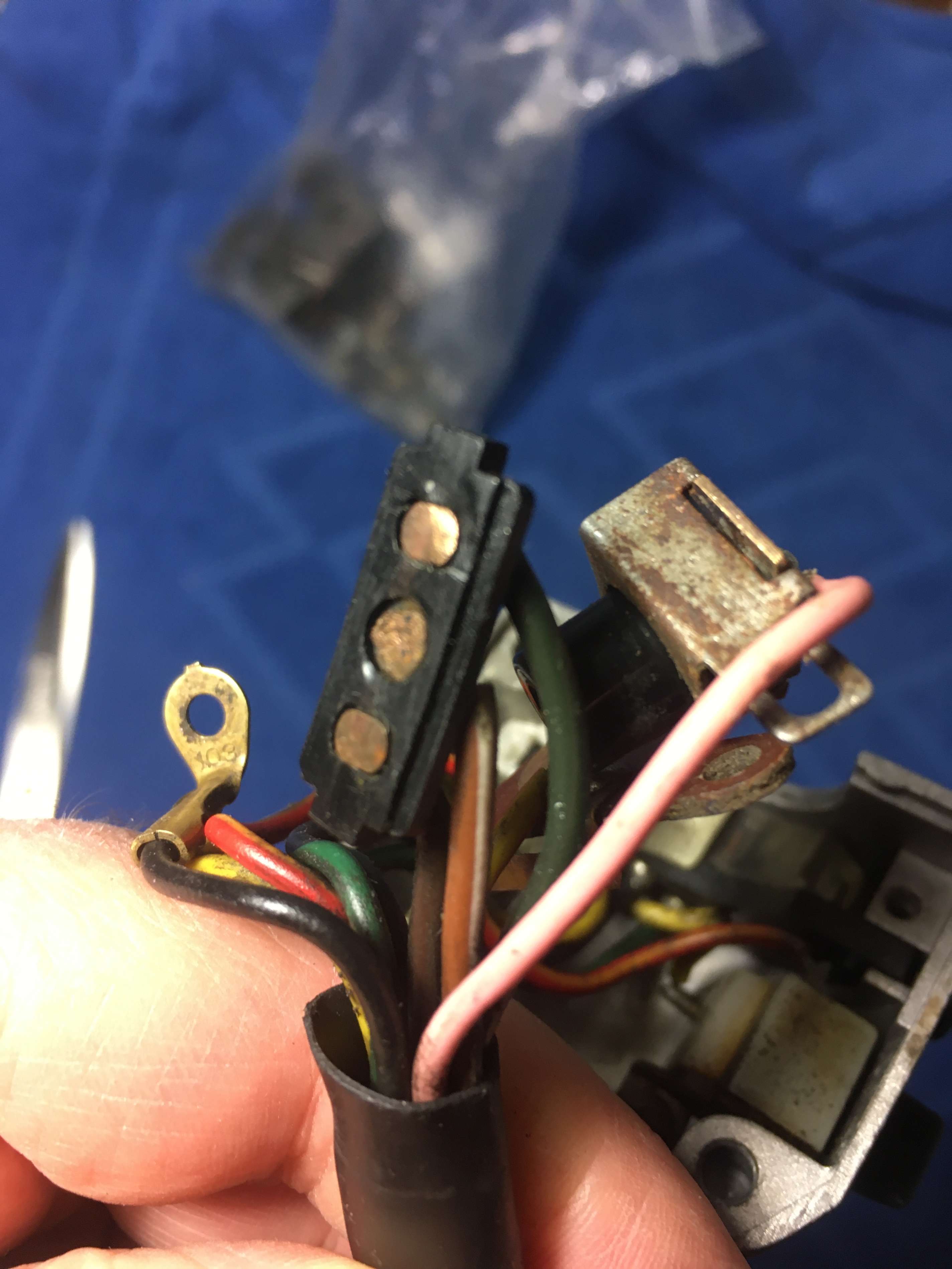

Inspection of the internals shows that mostly, the wiring is OK, if a little bit stiff and brittle with age.

The two major problems are

1) The horn button is broken off.

2) The indicator switch doesn’t work.

The horn is a puzzle. I am at a loss as to explain why so many RD and LC LHS switchgear assemblies have their horn button broken off.

Is it a weird geometry thing, where all crashes knock off the horn button?

Could it be that 2-stroke riders have a particularly heavy horn thumb?

Thinking about it, it is probably age, and the type of plastic which the button is made from becoming brittle over the decades.

Luckily, the horn button is available to buy new from various sources, albeit at what appears to be an outrageous mark-up.

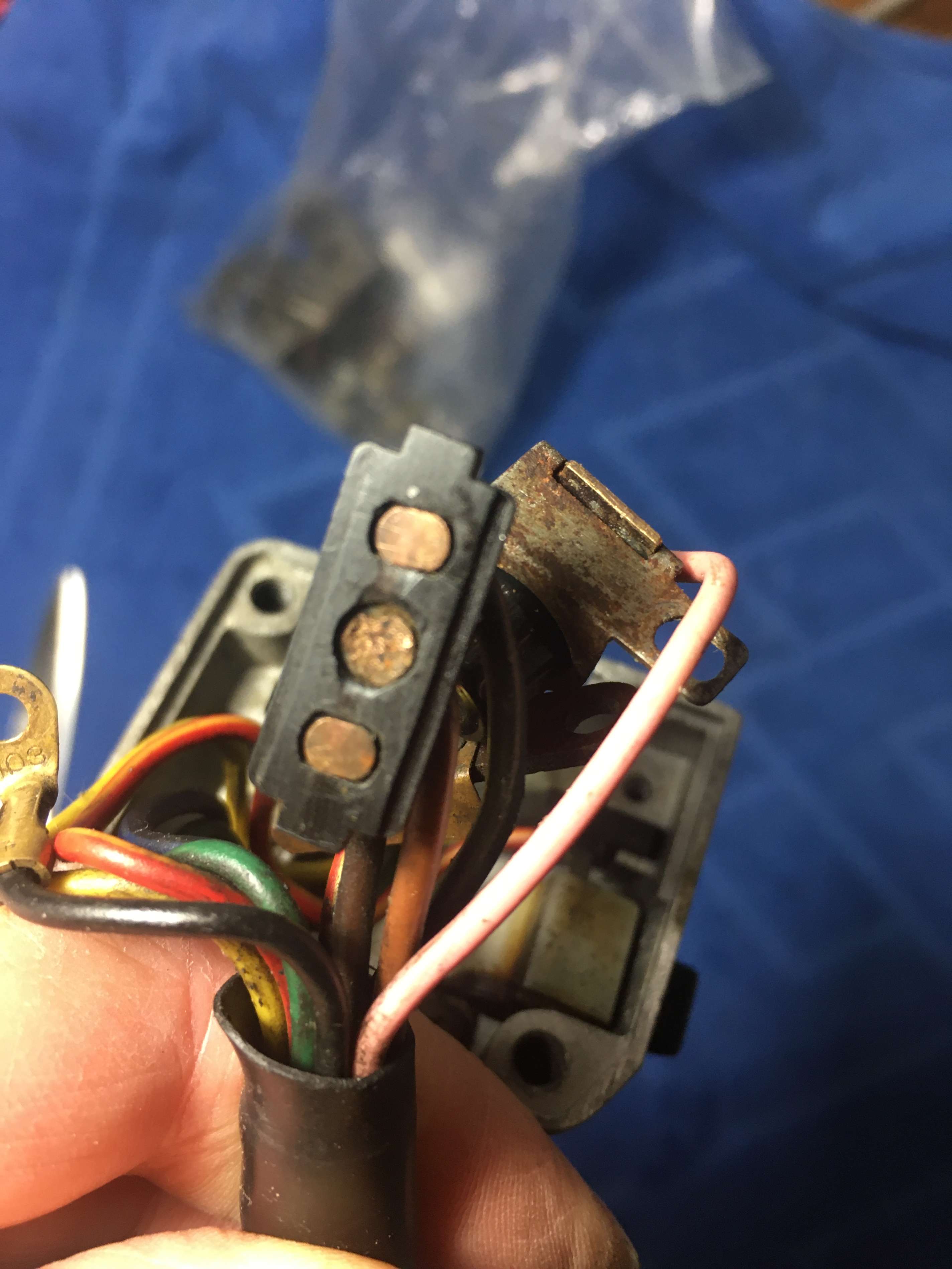

The indicator switch is another area which seems to afflict all aging Yamaha 2-strokes.

Due to the design, the centre pad of the three suffers from spark erosion every time it is switched, and consequently wears away.

My first thought was to replace, but it seems that you cannot buy this part separately.

So… repair then, but the copper pads are not removable, it seems the plastic is cast in place around the pads.

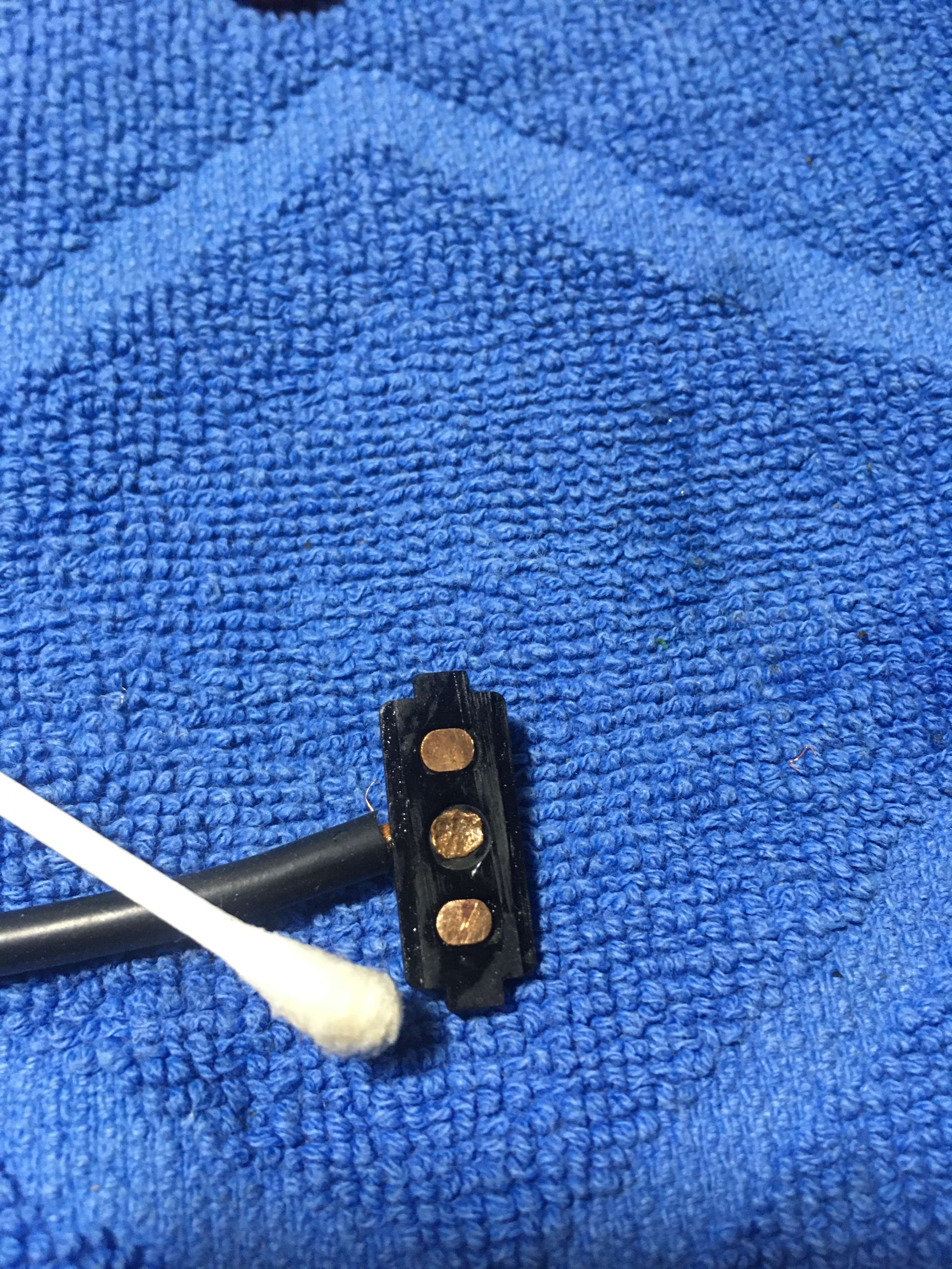

In desperation, I considered the implausible… Is it possible to copper plate the center contact pad back to a functional thickness?

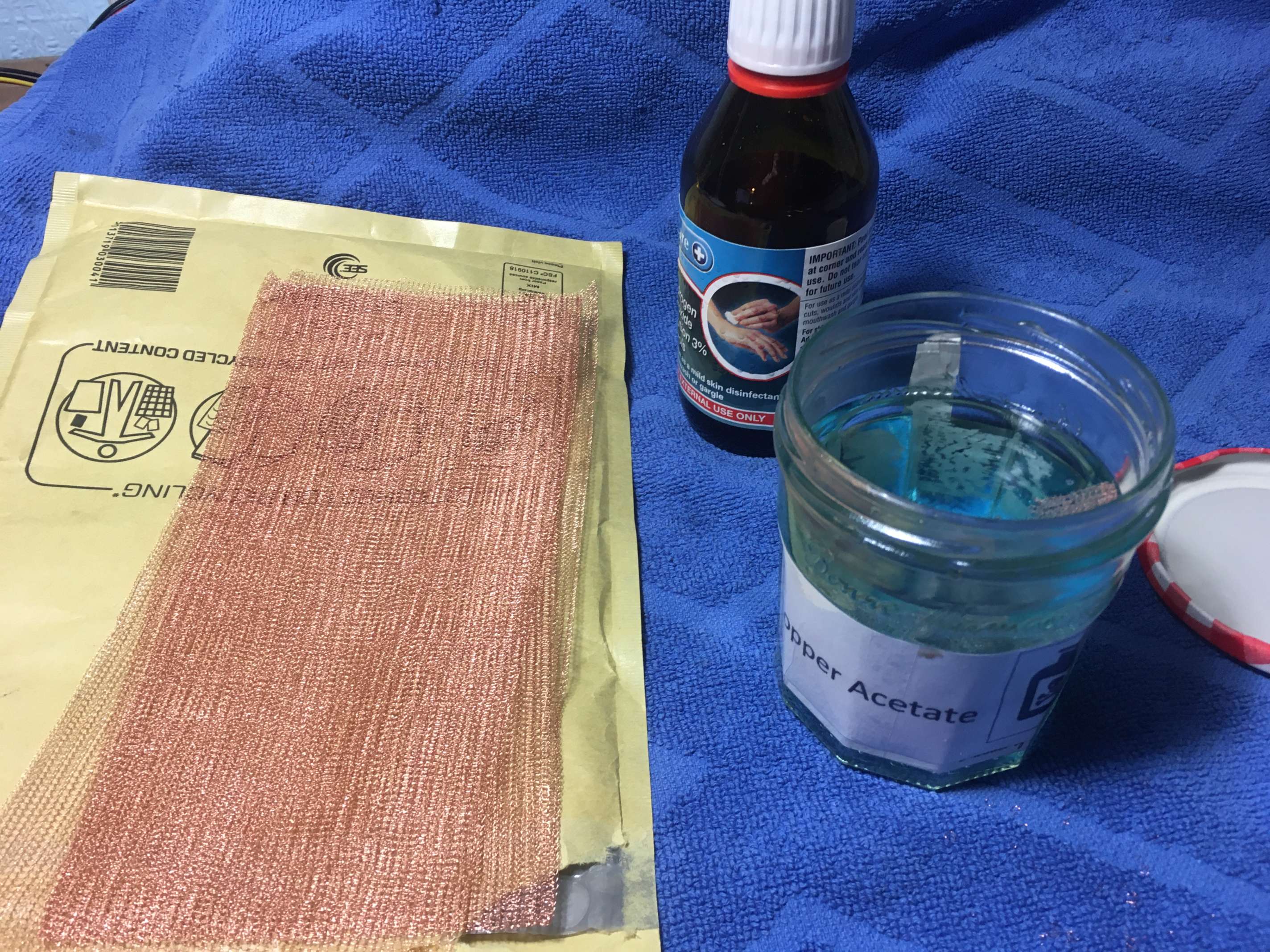

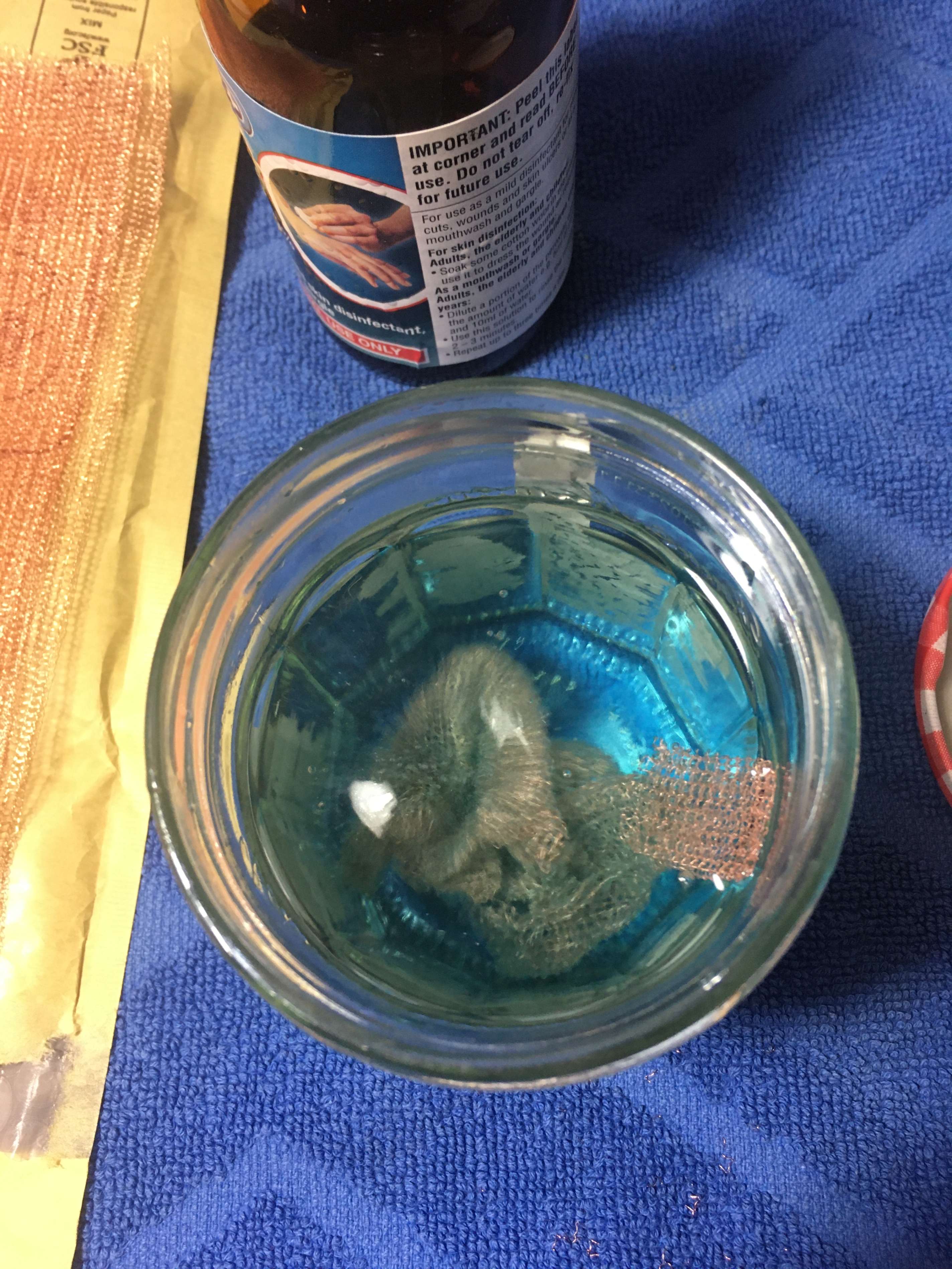

Assembling the parts needed for copper plating took a couple of days.

Hydrogen Peroxide, White Vinegar, some pure copper mesh.

Then following instructions as per this website.

As can be seen from the last picture above, the experiment was a partial success!

copper was precipitated onto the pad(s), but I got glorious crystalline tree structures instead of an increase in thickness.

This was probably caused by the fact that I simply left it to run for 24 hours rather than constantly agitating the work in the solute.

The experiment was ended in any case by the 40 year old plastic cracking in two.

Fortunately, in the course of hunting down other items in the parts bin, I found yet another old smashed up LHS switchgear, which had a serviceable contact pad.

5 minutes with a soldering iron, and I had internals complete to fit into the repainted cases.