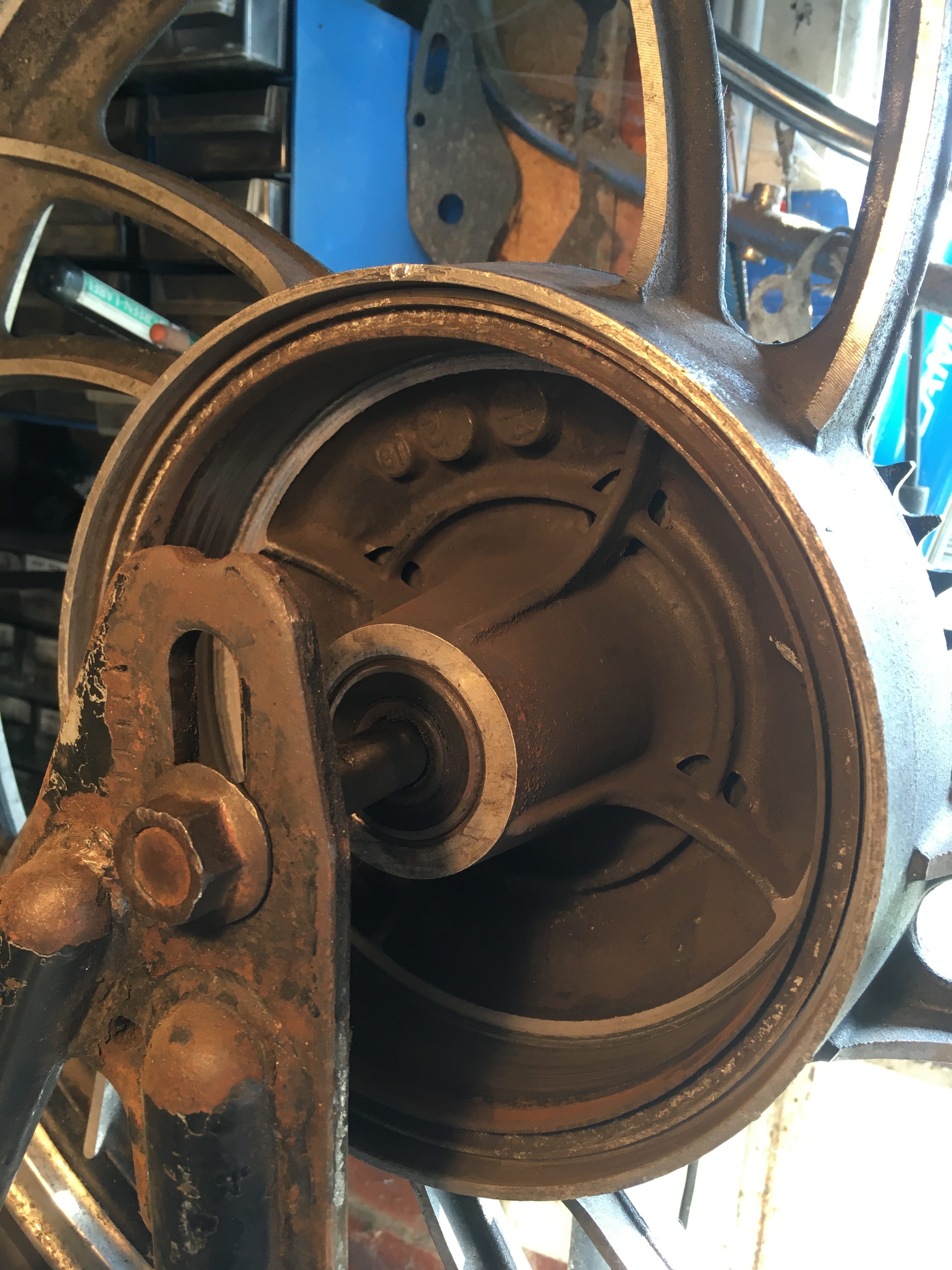

Sometime in the years in which the bike had lain fallow, the rear brake drum had become oval.

There are theories as to why this may happen, the most prevalent being that corrosion has occurred between the alloy of the cast wheel, and the steel/cast iron of the brake drum, which distorts the drum.

Another is that cast iron, being moderately porous, absorbs moisture, and simply swells with internal corrosion when left for long periods.

Whatever… My drum is now oval.

My first thought was to simply replace with another wheel, after all, 250 wheels are two a penny because everyone replaced with either 350 wheels for the dramatically improved cush drive, or with something altogether more exotic from a later bike.

This may have been true 5 years ago, but the current situation is that 250 wheels offered for sale on ebay are

a) More expensive than they have ever been

b) Encrusted with bright paints and rust

Clearly most of the wheels for sale have also spent the majority of recent years lying fallow, and there are no guarantees the any purchased wheel for £60 up to an astonishing £200, will have a brake drum any less oval than mine.

So to thoughts of skimming.

First to assess the damage, the wheel came off the bike, (my build is regressing piece by piece), and I cleaned up the drum as best I could with various abrasives.

I toyed with the idea of performing my own skim somehow with Heath Robinson contraptions involving drills clamped to swing arms with custom brackets and cunning use of dial gauges and verniers, but eventually came to my senses and realised I needed professional help.

My local bike shop had pointed me at an car brake specialist who had reputedly, a lathe with a bed big enough to skim a bike wheel.

On arrival at said establishment, I was met by an enthusiastic owner drawn outside by the dulcet tones of my 2 stroke exhausts, who had recently restored a Suzuki X7 of his own.

Unfortunately, the rumoured big lathe had left with it’s previous owner 14 years ago.

Plan B:

A search online using the terms “oval” “brake” “drum” and “RD250LC” led back to the RDLCcrazy forums, where one lead emerged as still trading.

An email to Terry Ives at Stotfold Engineers confirmed they could do the work at a price less than that I would pay for the lowest cost wheel offered on ebay.

I just have to remove the tyre and find a box big enough to pack it up for postage.