Not wanting to pay £100 for a genuine Yamaha OEM throttle cable, I did as so many others do, bought a pattern cable.

Rather than take pot luck on an ebay item, I sourced it from Norbo at RDLCCrazy.

It appeared to be decent quality, the bowden cables were a decent thickness, the cables have liners, and it all moved to and fro as expected.

the fitting to the carburetors went well, and the slides balanced without using excessive movement on the adjusters.

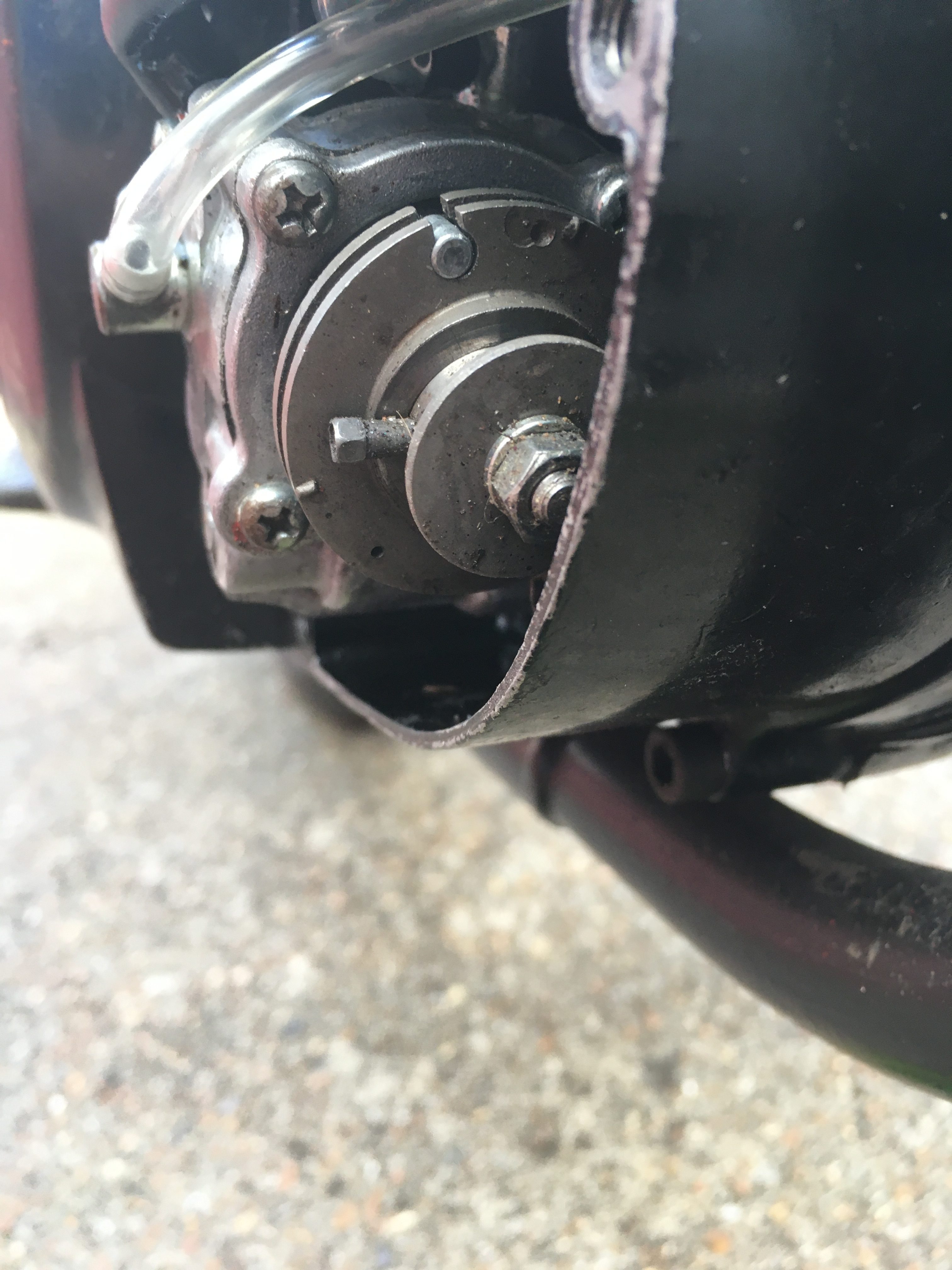

Then when attempting to set the oil pump, it became apparent that the cable was too short.

The oil pump segment of the cable that is.

With the adjuster set for maximum slack, the pulley on the pump had to be wound in some distance to fit the cable end, and then at full throttle setting, the pulley went way past the mark by about 10 – 15 mm.

A swift trip to Google showed that this has been a “feature” of pattern cables for the past 7 years at least!

I spend some hours hunting down the oil segments of throttle cables I have dismembered in the past, (having no need of them on a pre-mix bike).

I found two, but they had the same problem, and frankly, the quality of the cable was not as good as the one I had just bought.

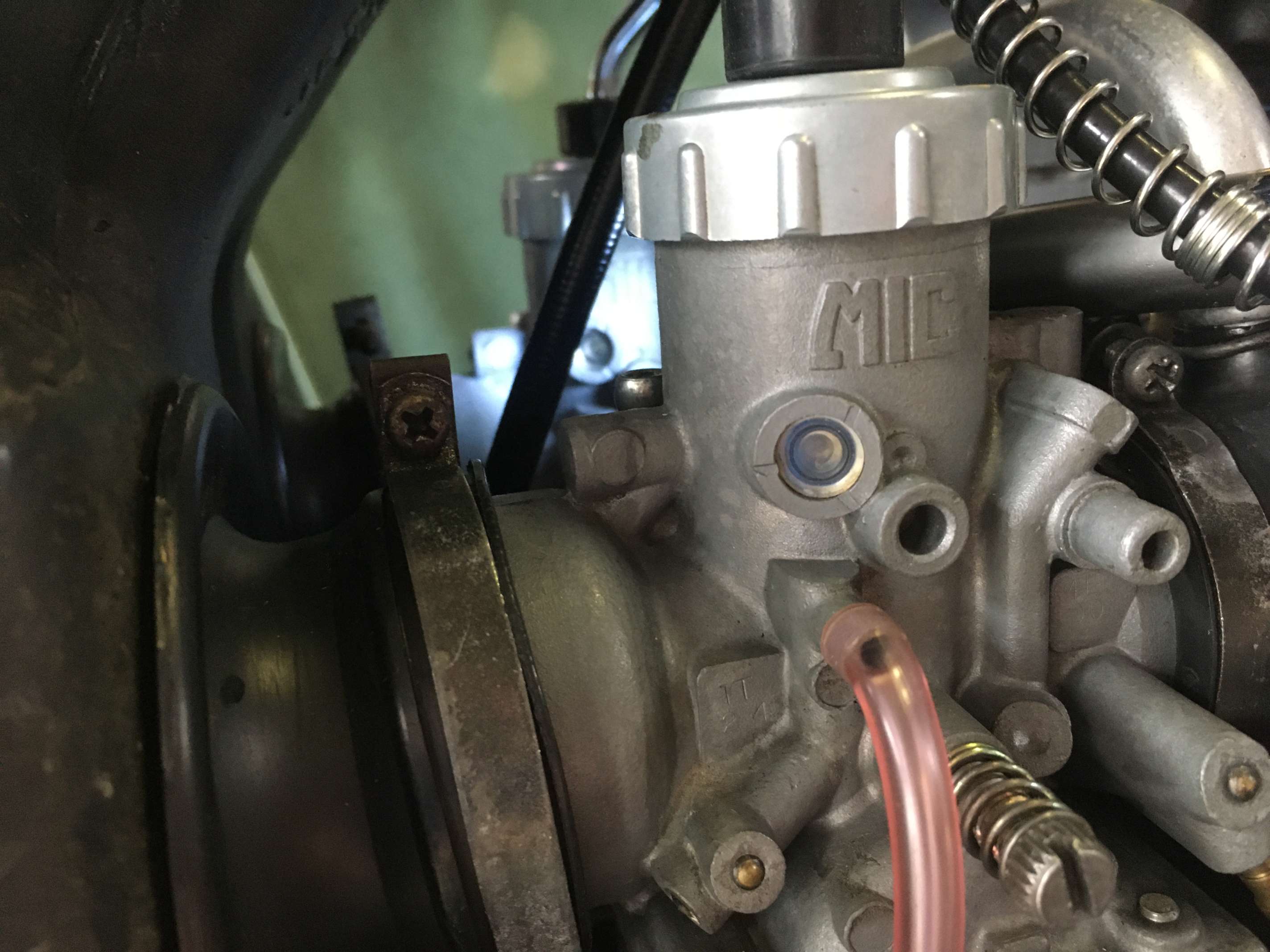

On the plus side, I located 2 pairs of RD/LC carburetor tops, complete with 45 degree angle cable guides.

Oddly, one pair has the washer and circlip fitment for the cable guide, and the other has the cable guides pressed in, the same as the Chinese cheapies I bought.

Both are marked MIC on the top, as per OEM.

Eventually, while researching something else, I found out that the circlip fitting is from 4L0/4L1 carbs, and the pressed fitting is from 31K carbs.

So if the exposed cable is too short, then all I have to do is shorten the outer sleeve. Yes?

I roughly measured and decided I needed the cable to be 15mm longer, so the outer sleeve needed to be 15mm shorter.

Measuring and marking the length to slice off.

Then stripping the plastic outer with a Stanley knife revealed the inner steel winding.

Grabbing with a pair of pliers to unwind a bit, then lacking any wire cutters strong enough to cut the tough spring steel, I used an angle grinder to finish the job.

As it happens, 155mm, or an extra 15mm, was just a bit too much. 10mm would have been better.

The cable adjuster is now at the limit of its adjustment the other way, in order to get the marks to line up.

if there is any cable stretch, I’ll need to put a washer or two where the cable enters the casing to give ma a bit more adjustment.

For now, it’s close enough.