Well I was rather hoping that I would connect it all up and everything would work.

Silly me!

The connecting everything together worked OK. the loom fitted to the frame and all the connectors were within reach to plug in.

And so to the testing.

Things to test…

- Horn

- Indicators

- Indicators idiot lights

- Neutral light

- Headlight dip

- Headlamp full beam

- pass switch

- Headlamp full beam idiot light

- Rear light

- Brake light switch front

- Brake light switch rear

- Low Oil switch

Initial test results, these work, everything else doesn’t…

- Horn

- Headlamp dip

- Headlamp full beam

- Headlamp Pass switch

- Headlamp pilot light

Further investigation shows…

Rear light is incorrectly wired and the wires are the wrong colour. the colour is because a Suzuki connector male/female pair have been soldered in instead of the originals. New connectors ordered.

The rear light connector on the loom has two wires connected to earth. This proved to be a short between two soldered wires underneath a bungle of insulating tape.

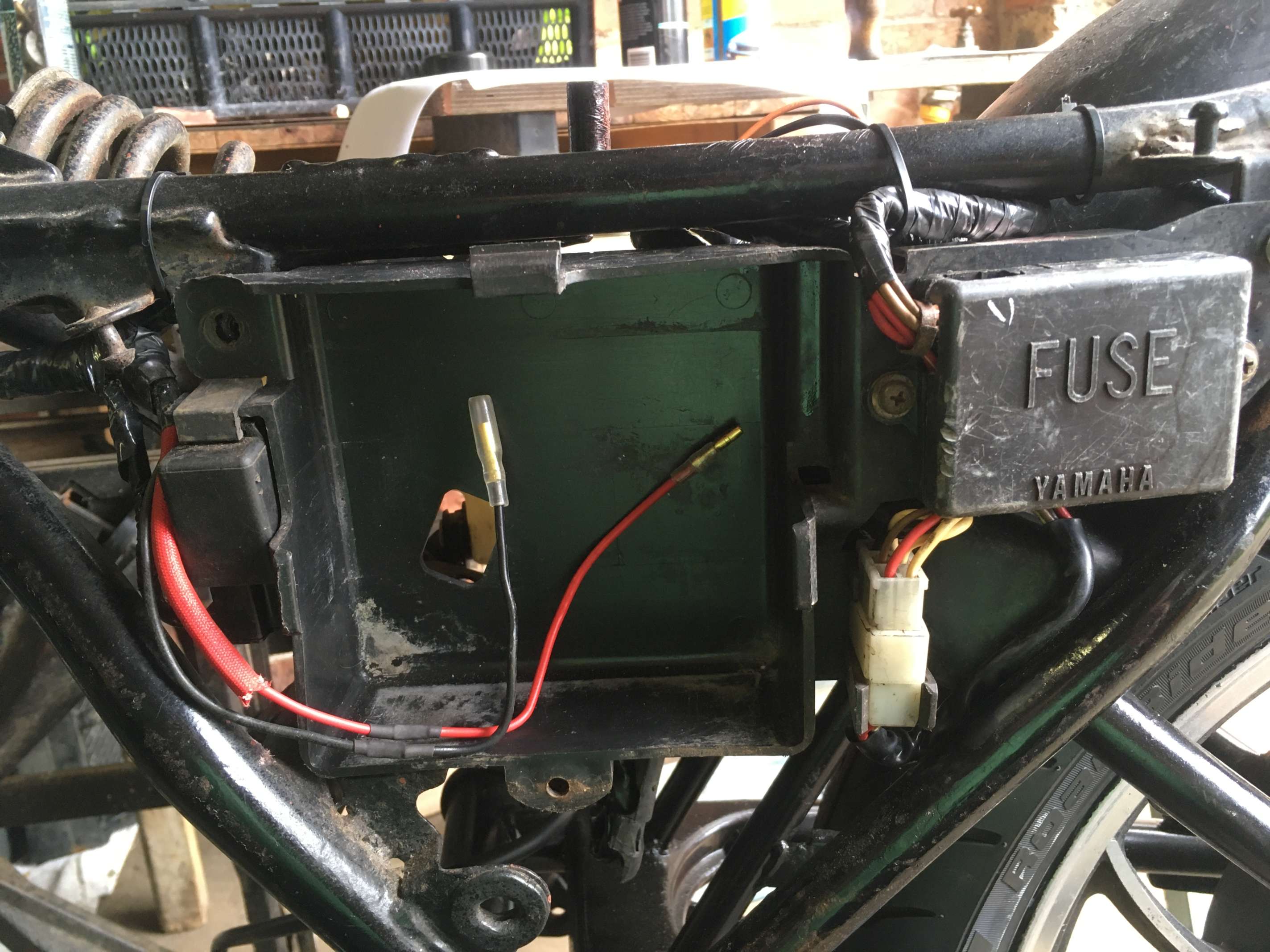

The connector which accepts the alternator connector from the engine is not the right one. An alternative 4 way has been soldered in and covered with insulating tape. Correct connector on order.

The indicators don’t work. The auto-cancel box doesn’t work, and the switch in the LHS switchgear doesn’t switch.

The Green/Yellow wire connecting the front brake switch to the rear light is broken somewhere in the loom, needing the loom to be unwrapped back to where I find the problem.

I’m still not sure why the idiot lights aren’t working. I need to open up the clocks and check the wiring through.

So it needs to come apart again, some unwrapping to happen, and this time I will be a little less optimistic and do some static continuity testing.

This loom has clearly had a hard life, and been “repaired” many times over an extended period of time!

I am wondering at this point why I didn’t just accept that I need to spend the cash and buy a new loom.

…but I persevered, and the loom came off the bike, and was unwrapped to see what the damage was inside.

there were a few dodgy repairs inside the bindings, which I remade, and one wire which had completely rotted away from it’s junction, but still connected by green powder.

it passed the full 12V when tested, but as soon as a load was applied the resistance shot through the roof so it passed virtually no current. Certainly not enough to make a 12V idiot bulb give out so much as a glimmer.

This wire was replaced completely, and the whole loom rebound.

I cleaned all the metal plugs and sockets in every connector with a variety of techniques, including acid baths, and much scratching with wet’n’dry, until I could see bare metal on all of the connectors. and gave them all a spritz with WD40 before plugging them together.

Lastly, I replaced the tail light connector bodge with a new connector, and fitted the correct connector to the loom for the alternator/neutral feed from the engine.

Everything now works, as far as I can test it… even the two stroke oil low level warning switch and light, with which I am largely unfamiliar having run my bikes on premix for the past 30 years.